Injection mould inspections and refurbishment

In practical terms all this gives an additional noticeable advantage in terms of working life of the components involved.

Making use of a line type pre-alignment system guarantees the coupling precision of the half moulds on every cycle, with a consequent reduction in stress in the components subject to wear (tapers). The benefits of the Long Life system obtained by applying the features described above are completed by using the half mould pre-alignment systems. The technological details that make the mould more efficient and durable Solutions such as Long Life by Sipa can double and sometimes even triple the working lift of mould components that are subject to wear, that is to say the stacks (the moulding components).Īpplying special coatings to the stacks, to give the surfaces subject to wear (tapers) improved characteristics that increase their hardness and reduce the friction coefficient, result in an exponential increase in working life. Typically, the behaviour of a mould in terms of wear is as described in figure 2, which shows both the progression for conventional moulds and for moulds with Sipa’s Long Life system.Īs can be seen from the graph, it is possible to extend the working life of the moulds enormously by applying specific treatments. The “ state of health” of a mould can be measured indirectly from the size of the flashes on the preform. In the following paragraphs we will look at the factors that determine mould productivity and the options that allow it to be used for a long time. READ ALSO: " Refurbishment centers: strong support for customers around the world" Monitoring the state of moulds, carrying out timely maintenance and selecting refurbishment services are procedures that make the working life of moulds longer, generating profits for the companies that produce PET preforms and containers. When bearing in mind the fact that the mould will be used for a long time, it is advantageous to include options to make the product more durable when drawing up the purchase agreement.

#Pet preform mold professional

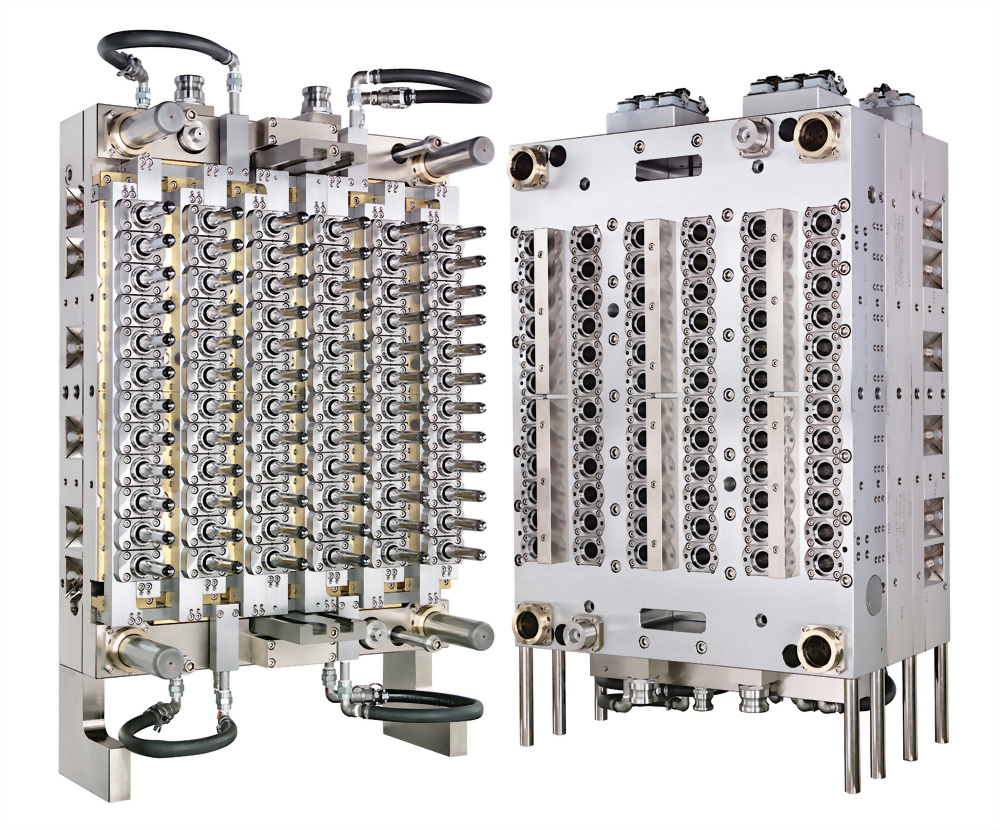

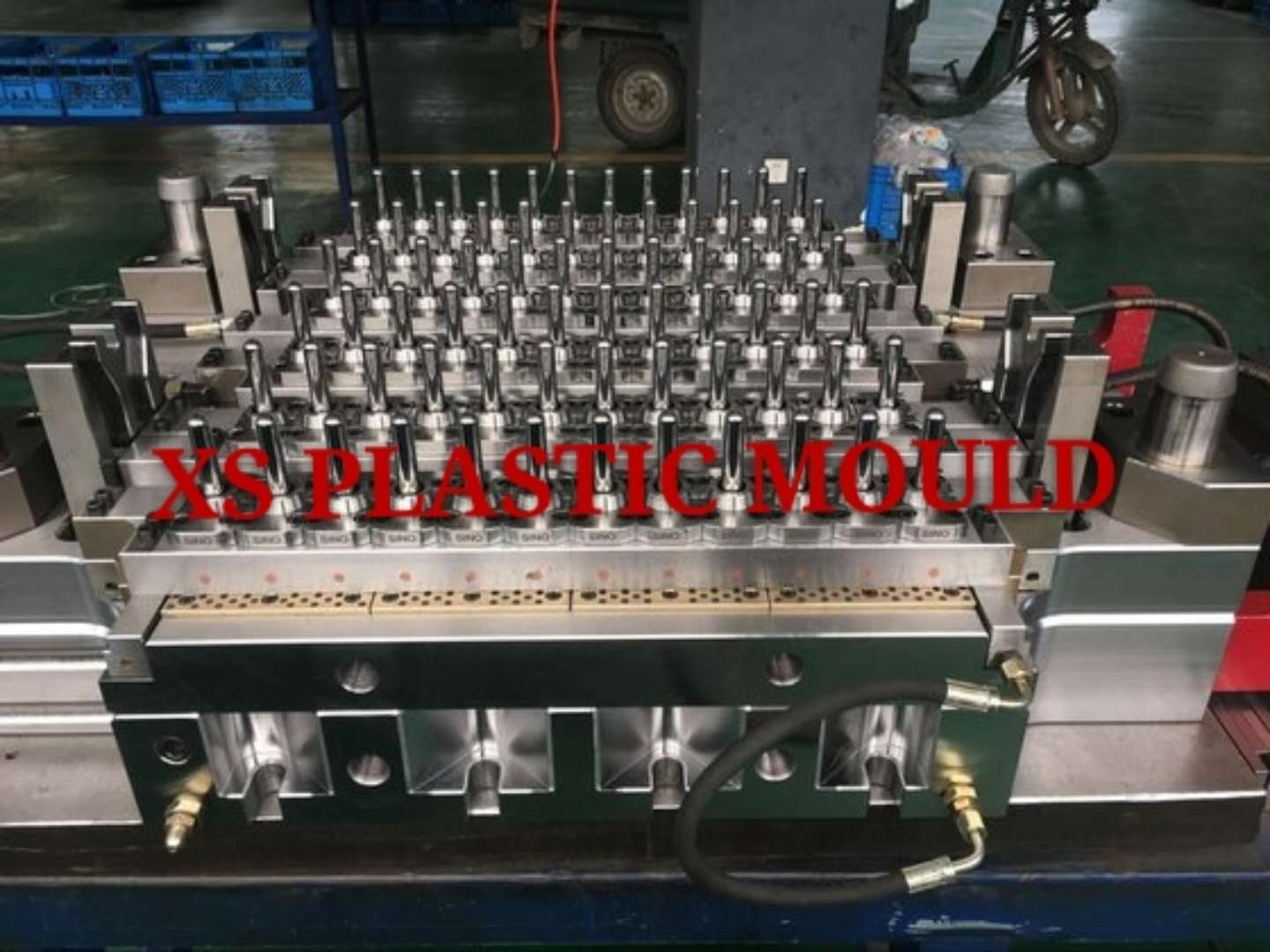

Technologists professional in after-sales line and excellent credit assures stable operation of the machines.Within the PET preform production process, the life of the mould is an important factor that has a considerable influence on the return on investment for a company. The screw neck is made and inspected strictly by the standard of Coca cola and the screw neck has been up to the standard of Coca cola. Inspection tools include projector, hardness tester, stress tester, eccentric tester, electric balance and other inspection tools. Offering temperature controller and voltage controller according to customers' requirement German intelligent temperature controller (PID continuous power controlling).ģ. All of these increases processing precision, good interchangeability and low eccentricity ≤0.10mm (perform length≤100).Ģ. Many machine tools are imported from America and Japan, such as Machine center, CNC lathers, EDM and so on. German Vacuum stove is imported for heat treatment of the components, which assures the hardness of components HRC45-HRC48. plate method avoids corrosion efficaciously and assures long life service of the perform molds.ģ. The main components of perform molds are made of S136 material (Sweden ASSAB).Ģ. Reasonable- designed cold water channels increase cooling effect and shorten the cycle time.ġ. Advanced hot runner system assures lower level of AA value.ģ. No cutting of valve gate is employed to reduce the labor cost.Ģ. We also design cold parts, hot runners and other main exchangeable components to fix on the imported perform molds.ġ. At the same time we can manufacture pet perform molds especially according to customers' injection molding machines. We supply special technology training and other good after-sales service.ĭemark has a powerful team for research and development, which is capable of manufacturing the pet perform molds with 1 cavity to 144 cavities including the pet preform injection molding system. Various kinds of processing equipment and detection measurement instrument are imported, as well as special drawing soft is applied in designing performs, samples and manufacturing testing mold. We invite many technical committee members and senior professors in mould line are as the technical consultants for our company. Demark, specialized in manufacturing 32, 48, 72 cavities PET Preform Mold, consists of technologists with rich experience, and senior engineers with master's degree and professional in 3D.

0 kommentar(er)

0 kommentar(er)